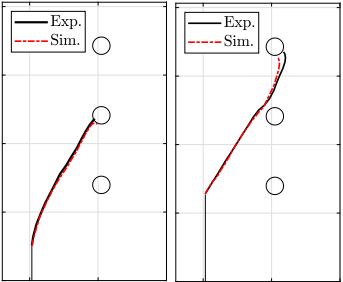

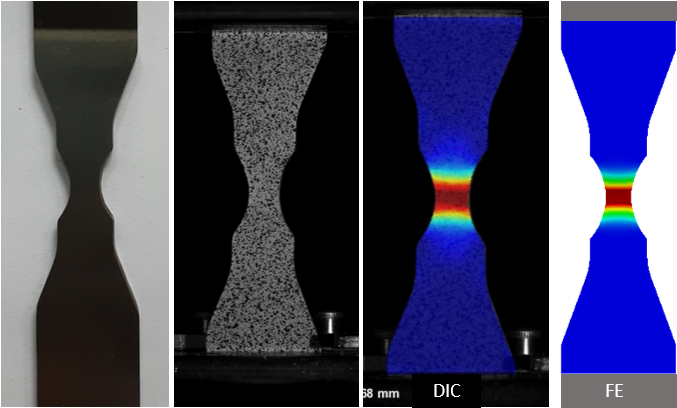

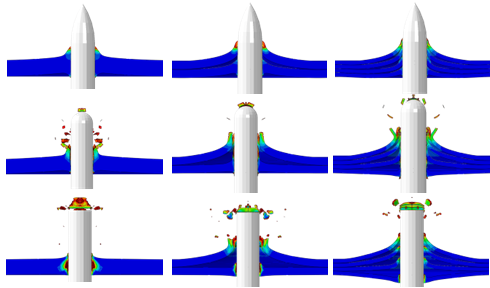

Elastic and inelastic deformation, along with the resulting failure of engineering materials, is one of the key limiting factors in engineering design and manufacturing. Ever increasing demand for materials with contradicting properties such as high strength and high ductility makes it vital to develop tools that can predict failure phenomenon, which requires a multi-scale approach. The aim of the IWPDF 2025 meeting is to discuss recent progress in the fields of plasticity, damage, and fracture mechanics. The workshop is organized by the Middle East Technical University, on 24-26 September 2025 in Istanbul, Turkey in a hybrid mode which gives the participants the opportunity to submit online contributions as well. This workshop welcomes both computational and experimental studies aimed at advancing the understanding of how material microstructure, loading conditions, and environmental factors influence the deformation, degradation, and failure of engineering materials. Contributions presenting novel engineering approaches in elastic deformation, plasticity, damage, and fracture are also encouraged. Beyond ductile deformation and failure, the workshop will also explore brittle fracture in various materials under different loading conditions, as well as fatigue, dwell-fatigue, and creep mechanisms. The workshop intends to provide an open platform for discussion on new directions in prediction and prevention of failure of engineering materials. The meeting is supported by European Structural Integrity Society and the full papers will be published in Elsevier’s open access Procedia Structural Integrity journal.

In addition to the general scope of the meeting, this year’s edition will also spotlight the following topics, featuring invited speakers and enriched by the support and contributions of different societies and institutions:

Data-Driven Analysis (Conference Attendance Grants Now Open)

This area examines how machine learning, deep learning, and artificial intelligence can be applied to study material behavior and predict deformation and failure mechanisms. These methods utilize large datasets from simulations and experiments to improve the accuracy and efficiency of predicting material responses. Recently, Materials Acceleration Platforms (MAPs) have been introduced in this field, offering a systematic approach to speed up material development by combining computational tools, automation, and data-driven insights. EU-MACE COST Action will support this year’s workshop by providing scholarships to students and researchers working in this field. Applicant whose abstracts focus exclusively on this field and are accepted for presentation will be eligible to apply for these grants.

The call for Conference Grants by EU-MACE is now Materials Challenges in Nuclear Energy Systems

Recent progress in nuclear energy technologies, notably next-generation fission and fusion reactors, imposes rigorous performance criteria on materials, driven by extreme environmental and mechanical loading conditions. The realization of these systems’ full potential necessitates the development of advanced structural materials and fuels exhibiting superior resilience to such challenging environments. Addressing these material demands requires a robust integration of computational modeling and experimental investigations. This year’s workshop will feature contributions from the European Energy Research Alliance (EERA) and the CONNECT-NM partnership, promoting discussions on recent progress in this field and available funding opportunities.Manufacturing and Material Forming

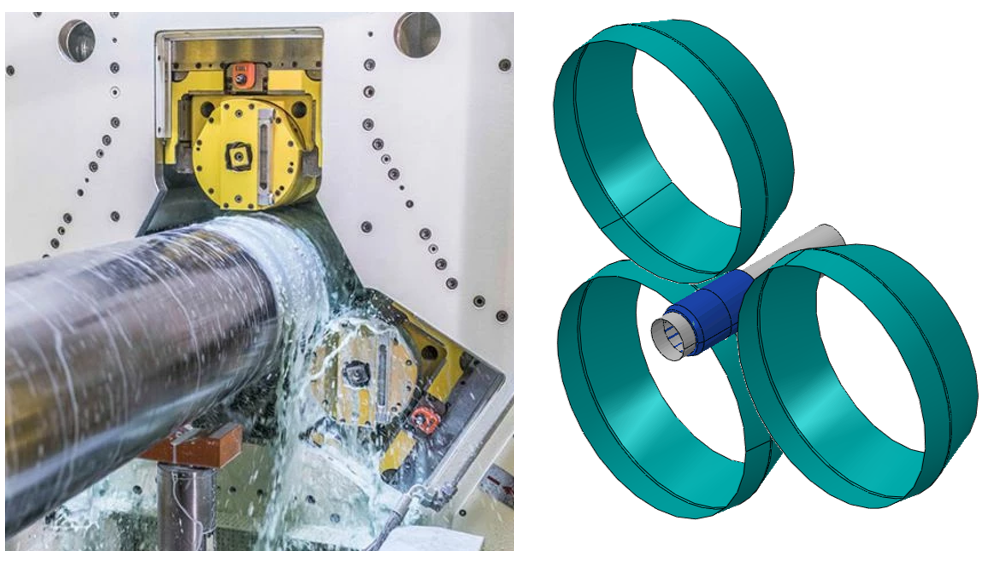

Metal forming processes in the manufacturing industry present numerous challenges, particularly related to plastic deformation and ductile failure. Advances in incremental metal forming and additive manufacturing have necessitated refinements in analysis and computational modeling to accurately predict material behavior under different deformation conditions. Sponsored by REPKON USA and REPKON, the workshop will host contributions in this field, presenting both analytical advancements and practical solutions.Download the Workshop Flyer here.

Workshop contact email addresses: wwwiwpdf@metu.edu.tr and iwpdf2025@gmail.com